Atarfil showed us a series of studies they were conducting to investigate and prevent failures in the material feeding systems of their machines.

All types of industrial machinery experience vibrations, and these feeding systems were not an exception. Therefore, they contacted us to develop a device capable of measuring vibrations in these material dispensing systems to check if there could be any anomaly in the vibrations that might lead to failures so they could take measures to prevent it.

Our solution

Given that there are two independent feeding systems in the machine, we opted to implement a device for each of them.

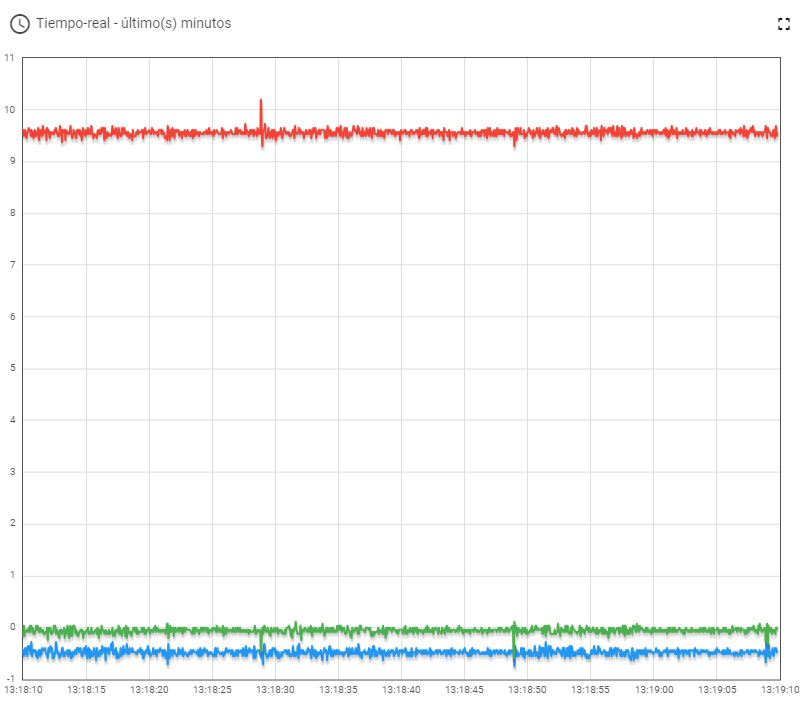

The device would be responsible for taking measurements of the vibrations of these systems and then sending them wirelessly to a display panel where any possible anomaly can be observed.

Vibration device features

The features of the device implemented for this project are:

- Measurement of vibrations on the X, Y, Z axes

- Data collection every 25 ms

- Remote transmission of data to the visualization platform

- Power supply from the electrical grid

- Prepared for an industrial environment

- Storage of collected data for long-term study

Would you need a similar device?

Contact us now and we will study your solution!

No comments