All manufacturing industries require raw materials in order to produce their goods. Additionally, these raw materials must be kept in warehouses or silos —as in our case—, where the various resins used in the Atarfil manufacturing process are stored.

Several factors depend on the filling status of the silos, including filling and emptying the silos to ensure that there is always material available for production, purchasing material in case it runs out, and knowing the fill level to avoid exceeding any limits that might compromise the factory’s systems.

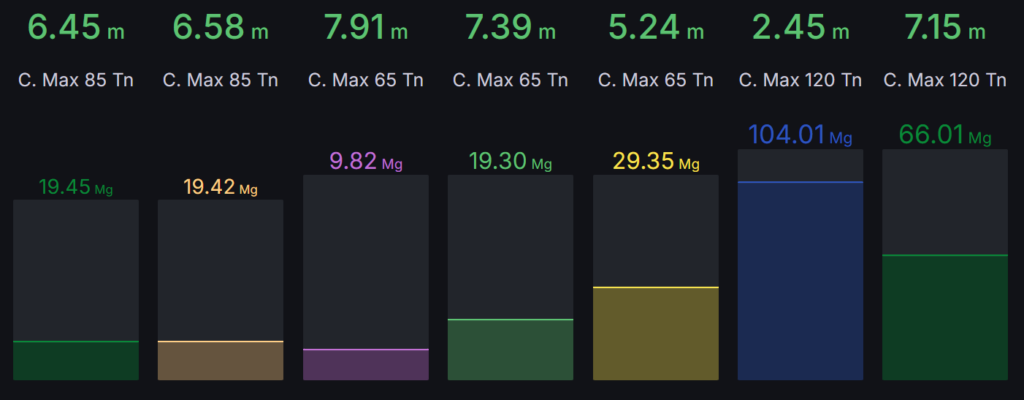

Prior to the installation of the ATGScan in Atarfil’s factory located in Granada, none of these variables were precisely known. These devices allow you to know the material amount in kilograms as well as the silos’ fill level.

Platforms for data visualization, like Grafana, which we used in our solution, can receive this data. We can create panels and visualization screens with this platform that display the silos’ current status as well as additional data that might be helpful to Atarfil.

No comments